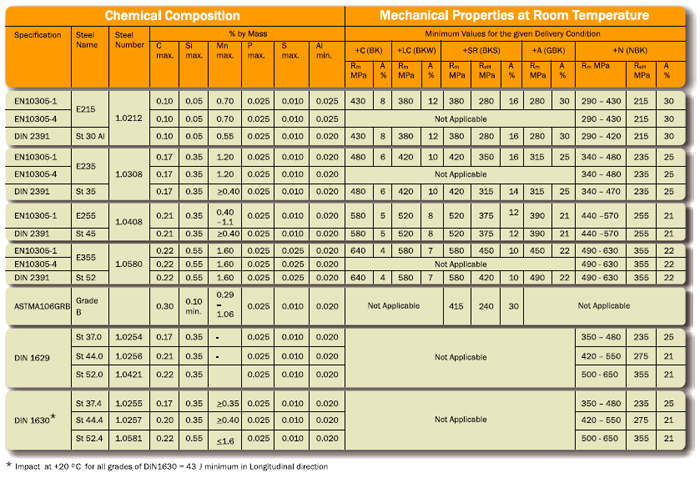

Chemical Composition |

Mechanical Properties at Room Temperature |

|||||||||||||||||||

Specification |

Steel Name |

Steel Number |

% by Mass |

Minimum Values for the given Delivery Condition |

||||||||||||||||

C max. |

Si max. |

Mn max. |

P max. |

S max. |

Al max. |

+C (BK) |

+LC (BKW) |

+SR (BKS) |

+A (GBK) |

+N (NBK) |

||||||||||

Rm MPa |

A% |

Rm MPa |

A% |

Rm MPa |

Rm MPa |

A% |

Rm MPa |

A% |

Rm MPa |

Rm MPa |

A% |

|||||||||

EN10305-1 |

E215 |

1.0212 |

0.10 |

0.05 |

0.70 |

0.025 |

0.010 |

0.025 |

430 |

8 |

380 |

12 |

380 |

280 |

16 |

280 |

30 |

290 -430 |

215 |

30 |

EN10305-4 |

0.10 |

0.05. |

0.70 |

0.025 |

0.010 |

0.025 |

Not Applicable |

290- 430 |

215 |

30 |

||||||||||

DIN 2391 |

St 30 Al |

0.10 |

0.05 |

0.55 |

0.025 |

0.010 |

0.020 |

430 |

8 |

380 |

12 |

380 |

280 |

16 |

280 |

30 |

290-420 |

215 |

30 |

|

EN10305-1 |

E235 |

1.0308 |

0.17 |

0.35 |

1.20 |

0.025 |

0.010 |

0.020 |

480 |

6 |

420 |

10 |

420 |

350 |

16 |

315 |

25 |

340 -480 |

235 |

25 |

EN10305-4 |

0.17 |

0.35 |

1.20 |

0.025 |

0.010 |

0.020 |

Not Applicable |

340 - 480 |

235 |

25 |

||||||||||

DIN 2391 |

St 35 |

0.17 |

0.35 |

>0.40 |

0.025 |

0.010 |

0.020 |

480 |

6 |

420 |

10 |

420 |

315 |

14 |

315 |

25 |

340 - 470 |

235 |

25 |

|

EN10305-1 |

E255 |

1.0408 |

0.21 |

0.35 |

0.40 -1.1 |

0.025 |

0.010 |

0.020 |

580 |

5 |

520 |

8 |

520 |

375 |

12 |

390 |

21 |

440 - 570 |

255 |

21 |

DIN 2391 |

St 45 |

0.21 |

0.35 |

>0.40 |

0.025 |

0.010 |

0.020 |

580 |

5 |

520 |

8 |

520 |

375 |

12 |

390 |

21 |

440 - 570 |

255 |

21 |

|

EN10305-1 |

E355 |

1.0580 |

0.22 |

0.55 |

1.60 |

0.025 |

0.025 |

0.020 |

640 |

4 |

580 |

7 |

580 |

450 |

10 |

450 |

22 |

490 - 630 |

355 |

22 |

EN10305-4 |

0.22 |

0.55 |

1.60 |

0.025 |

0.025 |

0.020 |

Not Applicable |

490 - 630 |

355 |

22 |

||||||||||

DIN 2391 |

St 52 |

0.22 |

0.55 |

1.60 |

0.025 |

0.025 |

0.020 |

640 |

4 |

580 |

7 |

580 |

420 |

10 |

490 |

22 |

490 - 630 |

355 |

22 |

|

ASTMA106GRB |

Grade B |

0.30 |

0.10 min. |

0.29 - 1.06 |

0.025 |

0.010 |

0.020 |

Not Applicable |

415 |

240 |

30 |

Not Applicable |

||||||||

Din 1629 |

St 37.0 |

1.0254 |

0.17 |

0.35 |

- |

0.025 |

0.010 |

0.020 |

Not Applicable |

350 - 480 |

235 |

25 |

||||||||

St 44.0 |

1.0256 |

0.21 |

0.35 |

- |

0.025 |

0.010 |

0.020 |

420 - 550 |

275 |

21 |

||||||||||

St 52.0 |

1.0421 |

0.22 |

0.35 |

0.025 |

0.010 |

0.020 |

500 - 650 |

355 |

21 |

|||||||||||

DIN 1630* |

St 37.4 |

1.0255 |

0.17 |

0.35 |

>0.35 |

0.025 |

0.010 |

0.020 |

Not Applicable |

350 - 480 |

235 |

25 |

||||||||

St 44.4 |

1.0257 |

0.20 |

0.35 |

>0.40 |

0.025 |

0.010 |

0.020 |

420 - 550 |

275 |

21 |

||||||||||

St 52.4 |

1.0581 |

0.22 |

0.35 |

<1.6 |

0.025 |

0.010 |

0.020 |

500 - 650 |

355 |

21 |

||||||||||

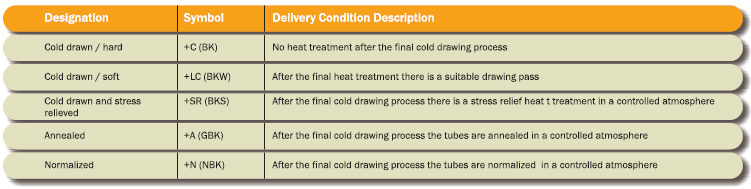

Designation |

Symbol |

Delivery Condition Description |

Cold drawn / hard |

+C (BK) |

No heat treatment after the final cold drawing process |

Cold drawn / soft |

+LC (BKW) |

After the final heat treatment there is a suitable drawing pass |

Cold drawn and stress relieved |

+SR (BKS) |

After the final cold drawing process there is a stress relief heat t treatment in a controlled atmosphere |

Annealed |

+A (GBK) |

After the final cold drawing process the tubes are annealed in a controlled atmosphere |

Normalized |

+N (NBK) |

After the final cold drawing process the tubes are normalized in a controlled atmosphere |

Each tube is oiled, internally as well as externally, and then packed into hexagonal bundles. This ensures that the tubes are corrosion protected and that they retain their straightness during transport. Upon request we can provide end caps and also wrap the bundles in LDPE sheets.

Each tube is oiled, internally as well as externally, and then packed into hexagonal bundles. This ensures that the tubes are corrosion protected and that they retain their straightness during transport. Upon request we can provide end caps and also wrap the bundles in LDPE sheets.